I have been in Sweden now for a week and have spent almost the whole time working on Akka. Not that there is anything wrong with her, but I have some plans for our future journeys and decided to do some upgrade work on her. And it started all this year. Here the list of little and large jobs that have happened last week.

Uncovering

As every year, the first thing is to get the tarpaulin off her. This is usually a quick affair and takes half an hour to an hour. Getting the supporting struts off is another hour. Add another half hour to pack everything up. Altogether 2 hours plus a bit for taking photos for my friends who will take Akka to bed in August.

Installing a proper speed and depth sounder

We currently have a single depth sounder that is just glued with some silicon to the inside hull. It works OK, although it sometimes looses the signal. Instead of indicating this by saying “error” or something similar, it picks a number to display. This is rather disconcerting when you are in the Skärgarden and think you are in 20 meters of water, when suddenly the display jumps to 1.9 meters! The other problem is that I don’t have a proper speed/distance indicator and rely solely on the GPS.

The installation started badly, as the hull had a step in depth in the exact location where I decided to drill the hole. This meant that I had to get the fibre glass out to make a proper flange for a water tight seal. Normally, it would have taken me an hour to install the triducer. With the fibre glass saga it was more like 4 (not counting curing time). Obviously yours truly is not an expert and laid on too little in the first go, which meant sanding and another 4 hours. Finally, it was a done, and I can proudly report that all is well and water tight.

Engine cooling intake valve

The valve for the engine water could no longer be moved and I am sure it has seen all 49 years of Akka’s life. It also had a very short nipple to attach the hose, where you could only place one clamp. This always bothered me and now was time to do something bout it. A relatively straight forward job – one would think! Unfortunately, the through-hull moved a little bit when I tightened the new valve and I was a bit unsure what to do. I looked OK and I decided a nice Sika seal on the outside would do the trick. I think it did but I will check very regularly.

Anchor chain

Anchoring in the Skärgarden is done from the stern. Period.

Akka has a very good arrangement with a 10 kg bruce (type) anchor, 5 meters of chain plus a 55 meter anchor band. Lovely and I never had an issue with it. It is right where I can handle the rudder and engine and the anchor always held. Of course there were situations where the ground was foul or I caught a sunk brunch or similar, but the set-up works here. Now, going further afield means a “proper” anchor. And here we go.

Anchor windlass

Having a lot of chain is great, but it means that I need a little help to get everything up again. Which means we need a windlass. The space available for a windlass is very limited on Akka and I got a Lofrans X1 which should do the trick. Drilling the various holes was relatively straight forward. I dug out a lot of Balsa and refilled it with epoxy to give it extra strength. I am not sure if the 2,5 cm hull will be OK. Maybe I have to strengthen it next year. We’ll see.

The installation went actually pretty well until I fed the chain into the windlass and followed the instructions. Unfortunately, the instructions did not mention the spring for the finger and I have yet to figure out how to get tha f%*$ing spring in

The pekken

The pekken is the typical Swedish platform at the bow. It is super handy to get on and off a Skäre and I cannot imagine how to sail in these waters without one. Unfortunately, we had a little accident last year. We were stern anchoring and made fast to a jetty. What I did not take into consideration, was that the jetty was on a large body of water and a large wave must have lifted the bow and stretched the anchor line so that the pekken came down on the jetty and was pretty bent. A couple of slats were broken. I could re-bend the metal frame and still had the original slats. All I needed was an ankarrulle to take the chain and anchor. A small job one would think. But it took me the best part of half a day to get it done. T

Storage

Victoria chides me that I have so much stuff on Akka. She is so right and I find it hard to get rid of stuff. In order get organized I constructed a shelf system with sliding crates for the cupboard. The cupboard is hardly used except for some boxes of screws and the dirty laundry. This was tricky and required a lot of shouting and swearing. The result is working out great and is such an improvement!

Grating

Akka had some wooden floor in the cockpit, but it showed signs of age and it broke in some areas. I made a new traditional grating that looks the business. Don’t ask how much time and money it cost, because it is insane. But it makes my heart go pitter-patter and that is what it is all about.

More solar power

Doing office work on the boat means that you need pretty soon somewhere a power socket. I have a number of additional Akkus, but it is always a worry when I run out of juice. So, a new deck-mounted solar panel plus a foldable/mobile panel add to the power sources on Akka. Obviously, with a new solar regulator that needed installing. Otherwise, it would have been too easy.

Wind instrument

Would you have guessed that it takes 6 hours to get a cable from the top of the mast to the bottom? I can tell you this was a tricky one. 5Almost 50 years in yacht and spar design are not available to Akka and the mast configuration for taking cables is a catastrophe. At least I think it is. The cables are actually running inside the keep! In the end it worked, and the cable is waiting to be connected.

Rudder repair

We did some small damage to the rudder last year. The anchor line must have run across the edge and we scraped off a bit. Nothing a little fibre glass won’t fix.

Cockpit drain

Almost done, one would think. Just when I thought we could push off, I realized that the cockpit drain were not draining. Too many leaves were obviously stuck in the drain and i could not clear the blockage. I tried everything for hours and since it was a public holiday in Sweden, no help was at hand. I pushed, I shoved, I jumped into the still rather cold Baltic, but no cigar. The next morning, the lovely people from Ramsmora took some air pressure to it and we were off!

Old faithfull

After launching, the engine did not start up too well. This came as a huge surprise as we call the diesel “old-faithful” as it is just very, very reliable. But the nice guy from Ramsmora quickly figured out that it was some air in the diesel system. He bled the system and all was well again. Phew!

Saftey lines

I guess 9 years of no use in anger won’t damage some pretty sturdy safety lines to hook onto when going forward. But then, maybe the sun does weaken the material. Anyway, I did not want to find out the wet way and decided to replace them.

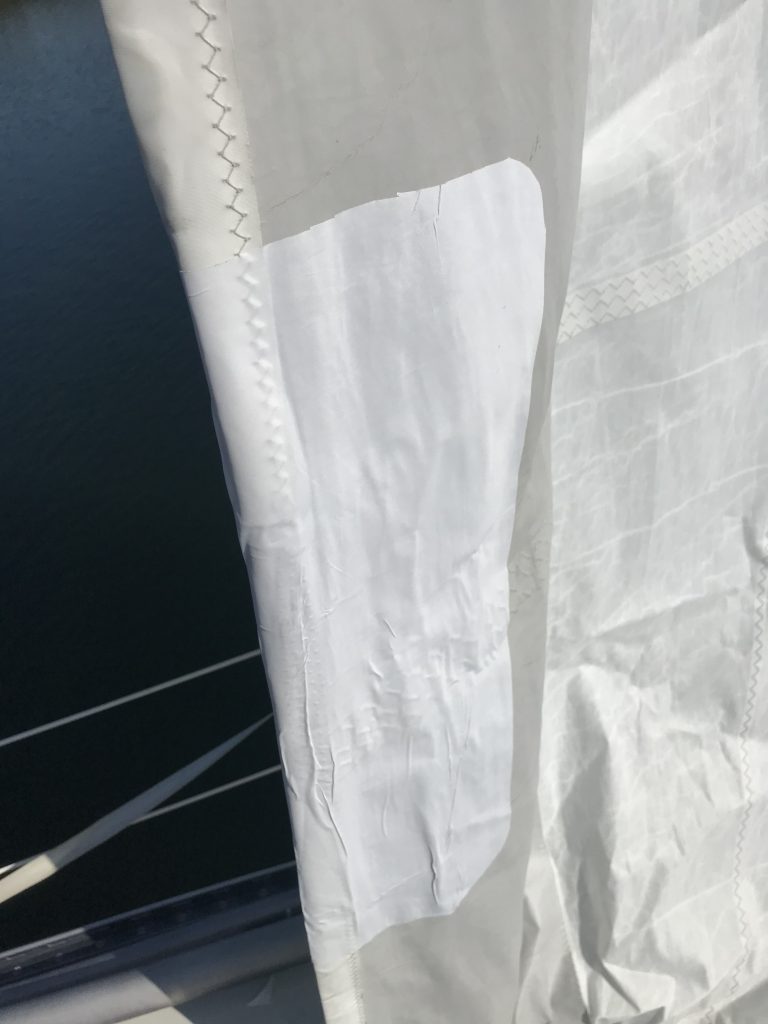

Sail repair

Not a big thing, but the leech cover has come undone on the genoa. I did not want to stitch it back on, so not to damage the cloth, and did a temporary repair with some glue-on repair material. Not a particularly nice job, but it will do the trick for the moment.

Wow, That is a lot of Good work! Can‘t wait to See it.